Energy Use

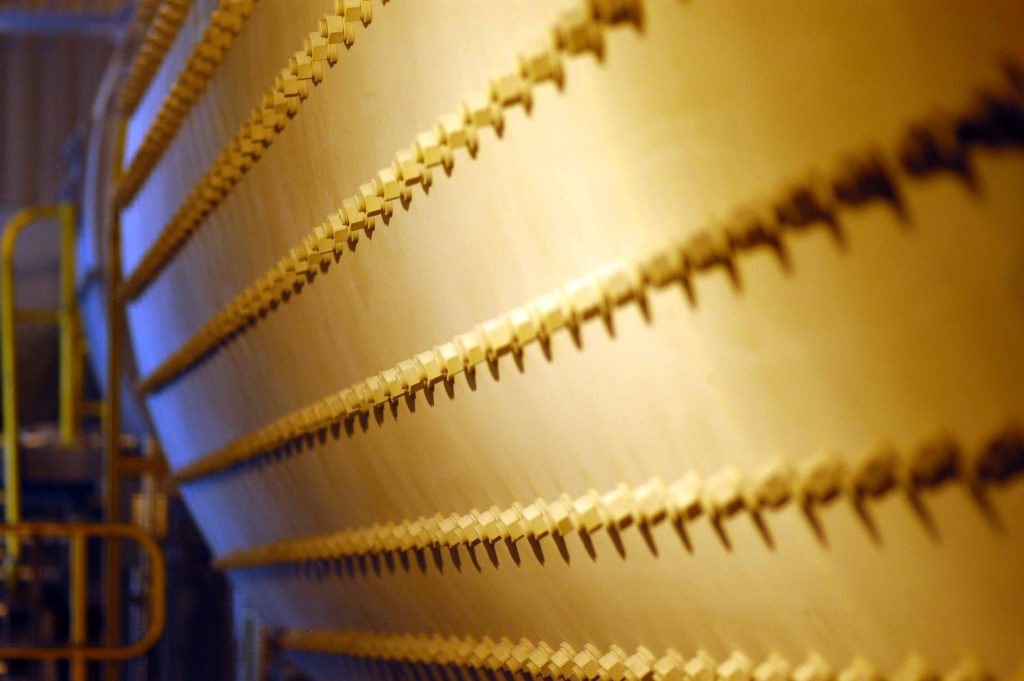

A cement manufacturing plant requires significant amounts of energy, mainly in the form of heat, to produce clinker. Significant amounts of electricity are then required during the milling (grinding) of clinker and other constituents to produce cement – the main binder in concrete.

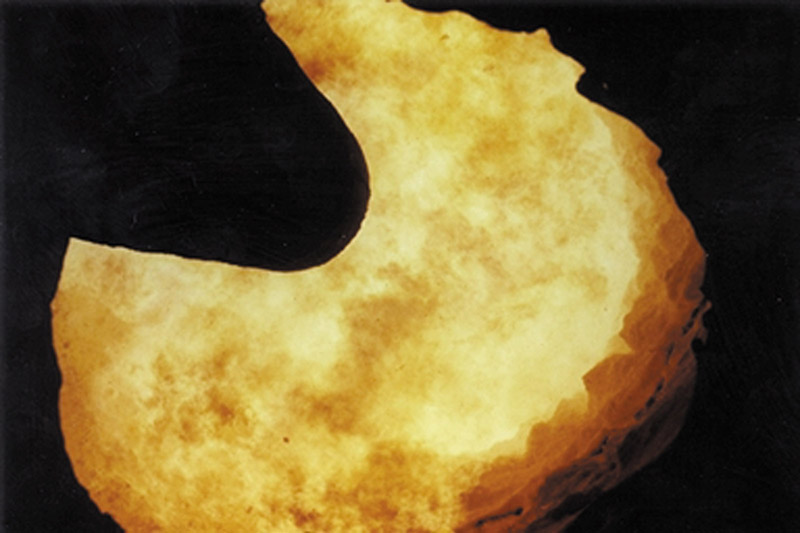

For integrated cement plants, energy in the form of heat is required to raise the kiln temperature to over 1,450 degrees Celsius required to produce clinker. This heat is predominantly generated using coal or natural gas as well as an increasing amount of alternative fuels.

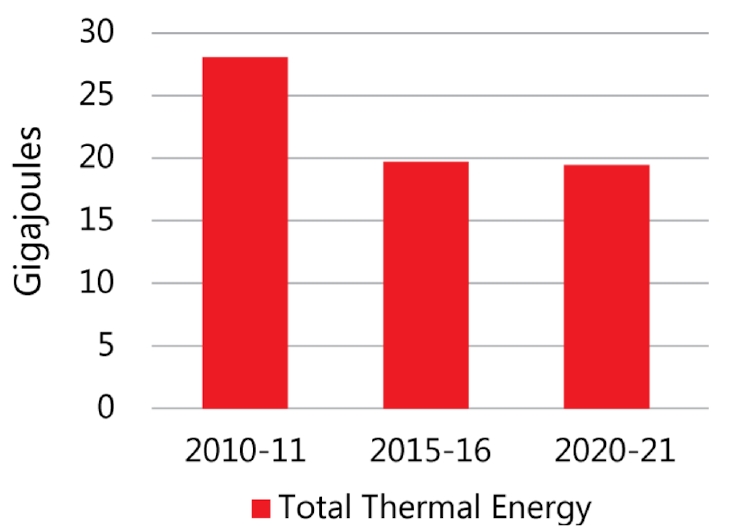

In total Australian cement producers consumed around 19.7 PJ of thermal energy, down 3 per cent year-on-year and down 30 per cent since 2010-11.

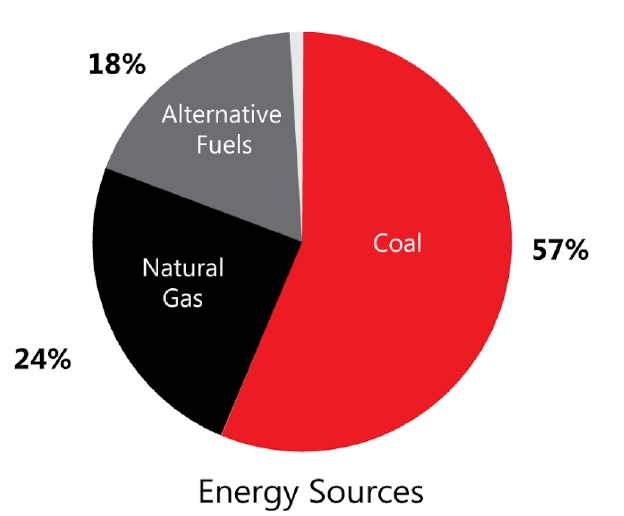

Of this 57 per cent came from coal, 24 per cent from natural gas, 1 per cent from diesel oil and other fuels. The remaining 18 per cent was derived from alternative fuels such as wood waste, solvents, used oil, spent pot liner and carbon powders.

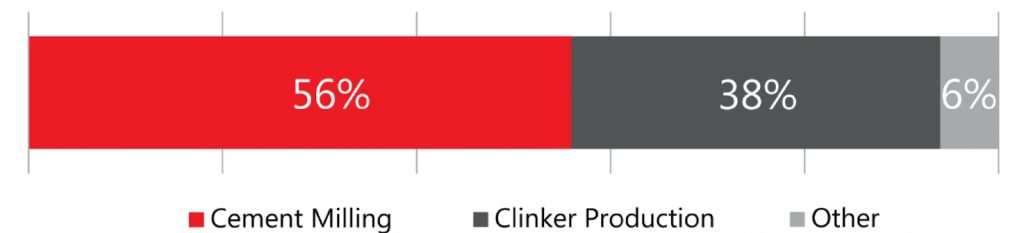

In terms of electricity usage, cement milling – the grinding of clinker, gypsum and other materials as required – accounted for around 56 per cent. A further 28 per cent is used in the production of clinker (i.e. preparing the raw meal and operating the kiln), with the remaining 6 per cent used to power other ancillary services on site